Part Identification

PSM Ltd offers two types of automated part marking, Laser Etching & Dot Peen.

Laser etching is a quick & clean way of part marking components. Individual components can be marked with identification codes, QR codes & bar codes on numberus materials including Stainless steel, high-grade steel, steel, Carbon steel, Copper, Iron, ferrous metals, Magnesium, Aluminium, Brass, Gold, Silver, Platinum & Titanium using different colour text.

Dot peen marking is an alternative way of permanently identifying a component but not as versatile as Laser etching.

Sawing

Vertical and Horizontal Sawing

PSM have large capacity sawing available both horizontal and vertical to accommodate all your requirements.

Sawing offers a quick method of extraction whether it be for an initial cut, up or precision extraction of Test Piece blanks.

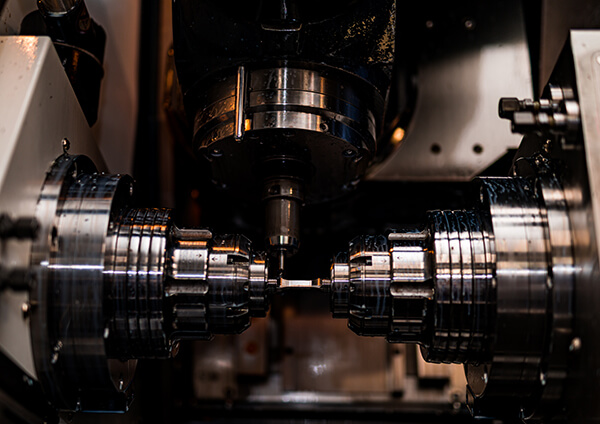

Turning & Mill Turn

Within our turning section at PSM we have some of the latest technology on hand. On site we have a pair of Doosan Puma MX 2100ST mill turn lathes with the capacity and the technology to offer solutions to cover most customer requirements. The twin turrets allow for the simultaneous OD and ID cutting on a part in the main spindle, and simultaneous milling and turning of components in the machines main and sub-spindle this enables multiple finished parts to be completed in one cycle.

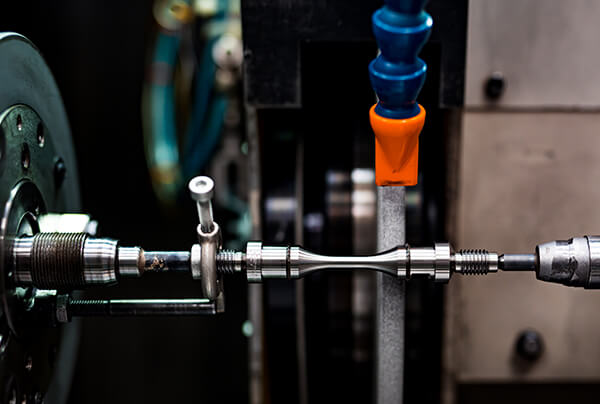

Grinding

At PSM Ltd our cylindrical and surface grinding capabilities are carried out with the ultimate in precision and to extremely tight tolerances for a wide range of industries including Aerospace, Motorsport & Defence. Our full CNC cylindrical & surface grinding facilities are ideal for batch runs from 1 off to high volume production runs. In addition to these facilities we can offer Optical & Thread grinding services.

EDM

Here at PSM we have an extensive Wire Erosion section with 11 machines on site plus an additional Spark eroder and Hole Drilling machine. We have a range of capacities to suit most size applications. We also have the latest technology in the form of “Clean Cut Technology ” for reduced re cast layer if required. We are happy to consider most sizes and shapes, don’t rule anything out give us a call first and lets see what we can do for you.

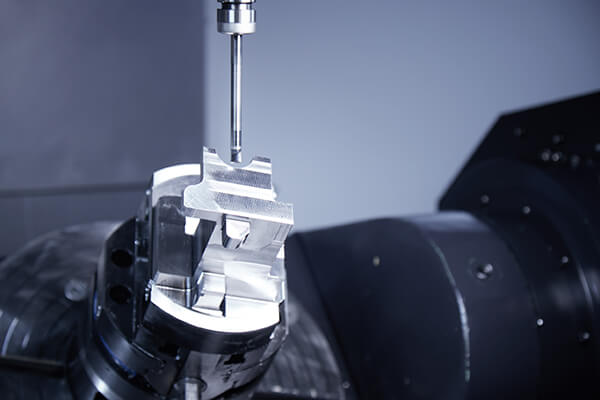

Multi Axis Milling

At PSM we can offer you a tailor made solution for all your milling requirements. Within our Precision Milling Cell, we have machines to cover the most demanding of set up’s. From one offs to larger production runs, we will have a solution for you.

We have the latest technology to hand from Doosan, including the DMM 400, 500 & 650 machines. The most noteworthy addition to this cell is the prestigious DNM 350. Offering 3+2 axis control, and the possibility of full simultaneous 5 axis machining, if required.

Give us a call and let us discus your needs.